Research Area:

Responsible:

Research Lines:

Project abstract

Future manufacturing will require high flexibility/adaptability and speed with respect to organisation of production and supply-chain management and it will require an increasing amount of services and inter-company collaboration.

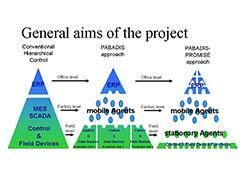

These future requirements especially concern control and networking of embedded control systems of manufacturing enterprises at ERP (office), MES (factory control) and production level. Taking these requirements into account and building on top of the successful FP5 Project PABADIS, the PABADIS'PROMISE project extended the idea of distributed control to an innovative architecture which incorporates both resource and product.

As designated outcome the PABADIS'PROMISE project will develop a new control architecture based on distributed intelligence, a new manufacturing ontology, a first embedded Real-Time agent platform for control, a new generation of RFID's, a new generation of field control devices, and building blocks for a new generation of Enterprise Resource Planning systems.

By these means it is possible to reach the following benefits:

- dynamic reconfiguration of assembly, production, and transport systems (integrate new machines, replace machines, or extract old machines) in a plug-and-participate way;

- dynamic design of control applications on demand related to the intended products;

- high degree of control code flexibility which enables an all-round plant, only limited by its physical parameters;

- integration of customer demands until their ultimate point of no return by physical/machine reasons;

- cross company wide co-operation over the whole supply chain.