Research Area:

Responsible:

Research Lines:

Project abstract

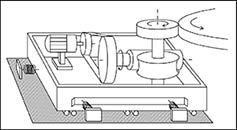

Mechatronic models of complex mechanical systems allow to assess the contribution of each component (be it mechanical, electrical, hydraulic) to the overall performance of the system. It is then possible to setup reliable simulators, that can be used to compare different choices made at component level. In this project they have analyzed a complex transmission chain, that is used in the first rotary axis of a large size machine tool manufactured by Pietro Carnaghi S.p.A., a world leading company in this field.

The goal was to identify the weak point of the machine, a source of limitations for dynamic performance.

Working in cooperation with the company staff, the DEI has studied the machine in detail, setting up a detailed simulator and quantifying the contribution of each component to the vibration modes. The project has been completed.

Project results

- Development in the Modelica/Dymola environment of an extremely detailed simulator of the transmission axis, that reliably reproduces the experimental data gathered on the real machine.

- Identification of a specific component of the transmission as the critical point.

- Proposal of alternative solutions, both from the control and from the mechanical design points of view.

- Publications:

S. Galbersanini, M. Galimberti, G. Magnani, G. Mazzola, P. Rocco, “Mechatronic analysis of a complex transmission chain”, 4th IFAC Symposium on Mechatronic Systems, Heidelberg, Germany, 12-14 September 2006.